Thermodynamic analysis of an automobile brake system

Abstract

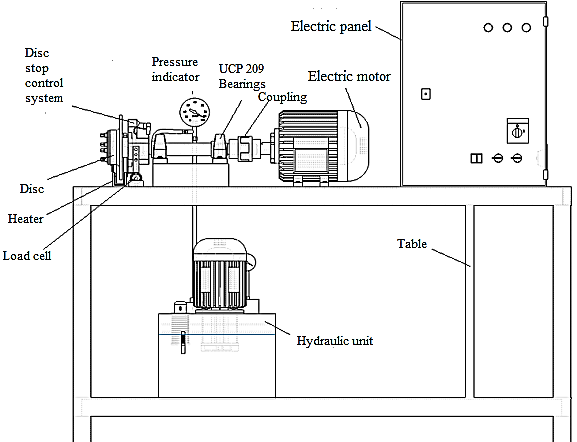

Energy and exergy analyses of an automobile's air-ducted disc brake system were performed in the current study. The experimental system consisted of the brake disc, calliper, linings, the electric motor to drive the brake disc, and a hydraulic pump to provide the oil pressure required to activate the brake unit. To simulate the braking process, the force is applied to the rotating brake disc at different brake pressures and the temperature change on the disc due to the braking action was measured. The braking system was evaluated thermodynamically by using these measurements obtained. The ideal brake force values were found around 200oC when continuous braking was adopted in the brake test. It was also noted that the brake force was decreased, and the braking process was weakened at the temperature of 250oC and above. Exergy destructions by the braking process were also calculated.

Full Text:

PDFReferences

H. Bayrakçeken, M. Düzgün, “Vehicles brake efficiency and braking distance analysis,” Gazi University Journal of Polytechnic, 8(2), pp.153-160, 2005.

A. B. Etemoglu, N. Etemoglu, B. Turkan, A. S. Canbolat, “Parametric Investigation on Thermal Performance of Vehicle Brake Systems,” El-Cezerî Journal of Science and Engineering, 2018, 5(2), 556-565.

A. Çavdar, A. Demir, & Kılıçaslan, “Determination of the weakening limit in braking and improvement studies,” Otomotiv Teknolojileri Kongresi, Bursa, Turkey, 2008.

M. Düzgün, Y. Yıldız, “Effects of cooling channel brake discs on braking forces and heat exchange,” 5. Uluslararası İleri Teknolojiler Sempozyumu (IATS’09), Karabük, Türkiye, 2009.

L. Rudolf, Brake Design and Safety, SAE, 228 (23) pp:51-70, 1995.

M. Erdem, D. Altıparmak, “Fren disk sıcaklığının frenleme performansına etkisi”, Journal of the Faculty of Engineering and Architecture of Gazi University, 29(2), pp. 425-432, 2014.

B. K. Satapathy, and J. Bijwe, “Performance of friction materials based on variation in nature of organic fibres Part I. Fade and recovery behaviour," Wear, No: 257, pp. 573-584, 2004.

J. Bijwe, Nidhi, N. Majumdar, and B. K. Satapathy, "Influence of modified phenolic resins on the fade and recovery behaviour of friction materials", Wear, No: 259, pp. 1068-1078, 2005.

D. Aleksendric, and C. Duboka, “Fade performance prediction of automotive friction materials by means of artificial neural networks,” Wear, No: 262, pp. 778-790, 2007.

P. Lingman, Integrated brake control, downhill driving strategies, Thesis for the Degree of Doctor of Philosophy, Calmers University of Technology, Department of Applied Mechanics, Göteborg, Sweden, 2005.

R. A. Dias and J. A. P. Balestrieri, “Energetic and exergetic analysis in a firewood boiler,” Revista De Cienci & Tecnologia, 12(23), pp.15-24. 2204

I. Dincer, and M. A. Rosen, “Thermodynamic aspects of renewables and sustainable development,” Renewable and Sustainable Energy Reviews, vol. 9, pp.169-189, 2005.

I. Dincer, M. Rosen, “Exergy as a drive for achieving sustainability,” International Journal of Green Energy, 1(1), pp.1–19, 2004.

M. Timur, “Design and manufacturing of the testing device for the friction coefficient of the materials used in disc-brake systems in automotive,” Master Thesis, Afyon Kocatepe University, Afyonkarahisar, Turkey, 2008.

Y. A. Çengel, M. A. and Boles, Thermodynamics an Engineering Approach, McGraw-Hill, USA, 1989.

A. Mavi, The investigation of change of brake force depend on temperature effect, on vehicle brakes, Master Thesis, Afyon Kocatepe University, Afyonkarahisar, Turkey, 2014.

A. Demir, A. Çavdar, İ. Kılıçaslan, “Determining and Improving of Brake Fading Threshold,” Automotive Technologies Congress, Bursa, 2008.

URN: https://sloi.org/urn:sl:tjoee63179

Copyright (c) 2021 Turkish Journal of Electromechanics and Energy

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Indexed in:

Indexed in: